Newsletter October 2002

The Role of Plant Life and Risk Assessment in Establishing a Cost Effective Structural Integrity Monitoring Programme

By R J Browne, Manager, Engineering Solutions, AEA Technology

Structural integrity monitoring can be highly effective in reducing the likelihood of component failure. However, it comes at a price and so must be properly targeted to be cost-effective. Assessment of the risk of failure (i.e. the likelihood and cost/safety consequences) can be used to identify and prioritise critical equipment items where a structural integrity monitoring programme may be justified. Life assessment for these critical items can tell us when it is necessary to commence the programme and what monitoring technique will be effective in identifying impending failure.

Detailed risk assessment is neither necessary nor practical for initial prioritisation of the large number of components of typical industrial plant. A simple qualitative or semi-quantitative assessment of the likelihood that the component may fail and of the cost, safety and possibly environmental implications, will generally suffice to identify and prioritise critical items. This can be quickly and consistently achieved by identifying pertinent in-service degradation mechanisms and then considering/scoring a number of relevant factors using carefully defined questionnaires or rules.

AEA Technology's Risk-Based Maintenance Planning Software (RBMS) offers a ready made framework for undertaking qualitative risk assessment and its effectiveness has been field-proven in numerous applications in the fossil power and oil refining industries. The output is a risk rating for each equipment item, presented as a point on the financial and safety risk matrices. Where the level of risk is 'undesirable', as in the illustration, a structural integrity monitoring programme may be identified so that activities are implemented to mitigate risk to an 'acceptable' level.

RBMS: Financial Risk Rating Display Screen

[click for full size image]

Having identified and prioritised the critical items of the plant where the cost of structural integrity monitoring may be justified on the basis of the cost, safety or environmental risk of failure, it is necessary to determine how the risk can best be managed. In many cases, some form of structural integrity monitoring will be appropriate. The choice of technique and when to commence its application will depend upon an estimate of the degradation rate and time to failure. For example, for a component nearing the end of its assessed life and where rapid degradation in its condition is predicted, some form of on-line technique will likely be necessary to give the required warning of impending failure. In other situations, the remaining life may be sufficient and the degradation rate sufficiently slow, such that examination at plant maintenance shutdowns will provide adequate assurance of integrity. In many cases, the life assessment may demonstrate that commencement of any structural integrity monitoring can be delayed.

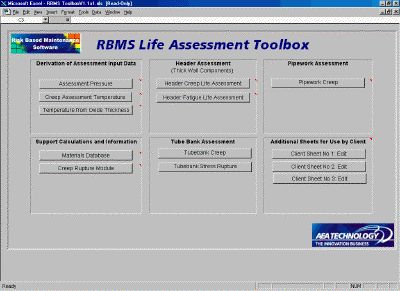

AEA Technology's life assessment software, RBMS.Toolbox, allows simple calculation of the safe remaining life of components operating under conditions where they are susceptible to a range of common degradation mechanisms, including wall thinning, creep and thermal fatigue. The calculations are based on inverse application of well-proven design methods. A comprehensive materials properties database is included in the software.

RBMS.Toolbox: Module Selection Screen

[click for full size image]

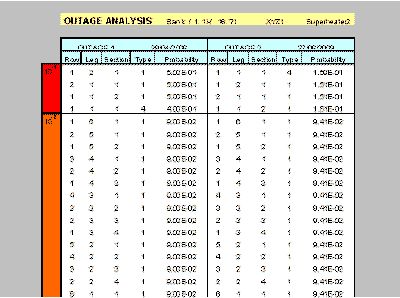

More sophisticated probabilistic calculation of the life of multi-component systems, such as tube banks, can be carried out using RBMS.Heater. The software calculates and displays the conditional failure probability as a function of future operating time in tabular and graphical formats. Recommendations, such as inspection, on-line monitoring or tube replacement, are displayed for implementation at future overhauls.

RBMS.Heater: Ranked Probability of Tube Failure at Next Two Maintenance Outages

[click for full size image]

The AEA Technology RBMS suite of software for risk and remaining life assessment of plant equipment has been designed to minimise data requirements so that the software can be easily and quickly used by busy plant engineers. The information generated is of real value in improving plant reliability/availability and establishing cost-effective structural integrity monitoring programmes, thereby reducing unit production costs.

In conclusion, considered assessment of the risks associated with a particular item of plant can lead to the establishment of a cost effective monitoring, inspection and replacement scheme. A tiered approach, with qualitative risk assessment at the one end ranging through semi-quantitative to a fully quantitative assessment for high risk items, minimises the costs of establishing an effective structural integrity monitoring programme and makes the best use of scarce labour resources. The systematic application of risk and life assessment across a plant leads to a reduction in unit production cost through increased statutory inspection intervals, reduction in the number of forced outages and well-targeted plant refurbishment.

Further information on AEA Technology's range of asset life management services and software are available at www.solutionsinengineering.com or contact us by e-mailing to integrity@aeat.co.uk.

^top